Quicker, easier and cheaper

Jigs, fixtures, molds, robot grippers. As the technology developes more industries can benefit of additive manufacturing. One offs, like a fixture, can be produced quicker, cheaper and using less material compared with traditional technique.

Using advanced termoplastics with higher melting points, it´s possible to reach enough impact resistance, toughness, and rigidity for alot of manufacturing tools. In that way companies can cut cost from changing from expensive metals to plastics changing traditional tools to AM.

kilos/h

Maximum speed of our printer.

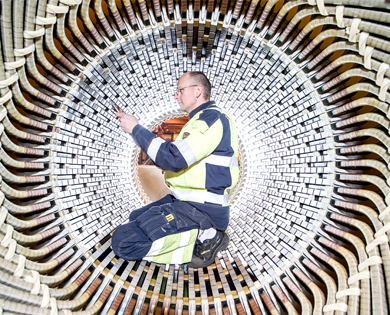

Complex fixtures for ABB

At ABB Coil Center in Sweden they choose to try AM for their complex fixtures when winding copper for motors. Their old fixtures was made out of wood by very skilled craftsmen, now retired.

By printing diagonal Sculptur managed to produce fixtures that could withstand the force when winding copper, but also fit the measurements demands for a high quality industry company like ABB.

Newsletter

Be the first to know of our product launches. We don’t spam and your email address is safe with us